Produce 3D printing parts hassle free

Choose from the range of printing technologies we offer

Schedule A Call Get QuoteAbout 3D Printing

Advantages

- Design Flexibility: 3D printing allows for the creation of complex and intricate designs that would be difficult or impossible to produce using traditional manufacturing techniques.

- Cost-effective: 3D printing eliminates the need for expensive tooling, molds, and other equipment required in traditional manufacturing, making it cost-effective for small batch production.

- Customization: 3D printing enables the production of personalized and customized products for specific customers, markets or applications.

- Speed: 3D printing can produce parts in a matter of hours, reducing lead times and enabling faster product development cycles..

- Waste reduction: 3D printing produces less waste than traditional manufacturing methods as only the required material is used in the process.

Disadvantages

- Limited Material Selection: 3D printing is limited by the materials that can be used in the process, which can result in limitations in strength, durability, and other characteristics.

- Surface Finish: 3D printed parts often have a rough surface finish that may require additional finishing operations.

- Part Size: 3D printing has size limitations, and larger parts may require assembly or printing in multiple parts.

- Cost: While 3D printing is cost-effective for small batch production, it may not be cost-effective for large scale production.

- Accuracy: 3D printing can be less accurate than traditional manufacturing processes, particularly for parts with fine details or tight tolerances.

Applications

- Rapid prototyping: 3D printing allows for quick and cost-effective production of prototypes and models, reducing the time and cost involved in traditional prototyping methods.

- Manufacturing: 3D printing can be used to create complex and intricate shapes, making it useful in the production of various parts and components.

- Medical: 3D printing is used in the creation of medical implants, prosthetics, and other medical devices.

- Aerospace: 3D printing can be used to produce lightweight, complex components for aerospace applications.

- Automotive: 3D printing can be used to create custom parts for automobiles, as well as for prototyping and testing.

Why Choose EasyM's 3D Printing Service?

The painful days of searching for right manufacturers, waiting for quotations and parts production are over. EasyM has brought 3D Printing online! We maintain our own 3D Printing facility and a large network of certified manufacturing partners so that we always have someone to work on your orders.

Cannot find the right 3D printing technology? We maintain a wide range of technology portfolio so that you get access to the technology you are looking for right from your laptop.

Hate waiting for quotations? We employ dedicated engineers to provide you with an estimate project cost so that you save valuable time. And it does not stop there, our engineers will provide feedback for your designs to make them suitable for manufacturing and reduces cost.

Have a large order with less lead time? No problem. We can parallely process your order at multiple facilities so that you receive your parts on time.

Did not find right materials and finishing? Try us. We offer a wide variety of metals and plastics and a combination of finishing processes suitable with each material. But wait there is more, if you are unsure about your specifications our engineers will help you select right specifications for your specific use case.

Our 3D Printing portfolio

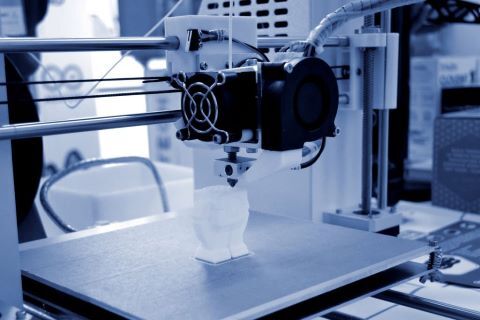

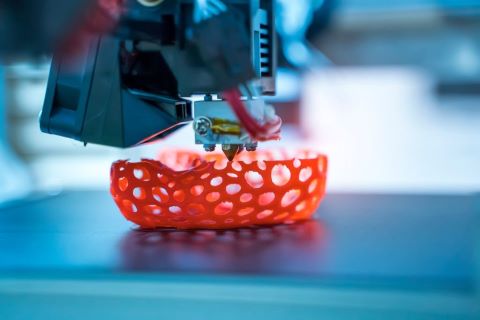

Fused Deposition Modeling (FDM)

Stereolithography (SLA)

Selective Laser Sintering (SLS)

Digital Light Processing (DLP)

Polyjet

HP™ Multi Jet Fusion

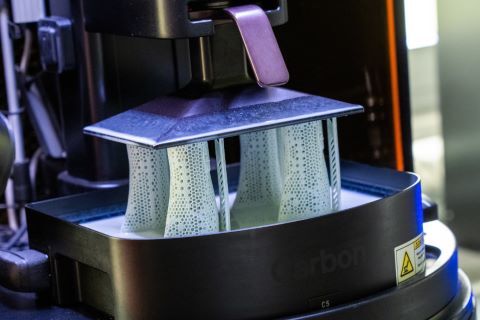

Carbon™ Digital Light Synthesis

Binder Jet

Direct Metal Laser Sintering (DMLS)

FAQs

Although material option depends on the technology of 3D Printing selected, here is a combined list materials that are possible:

Metals:

- Stainless Steel

- Maraging Steel

- Aluminium

- Nickel Alloy

- Tungstun-Bronze

- Titanium

- Inconel

Plastics:

- PP

- Resin

- ASA

- ULTEM

- ABS

- PC

- Nylon

- PPSF

- TPU

Although the type of finishing process available depends on the exact material and the printing technology used, here is a combined list of finishing processes that are available:

- Colour Dyeing

- Media Tumbled

- Vapor Smoothing

- Quick CLear

- Nickel Plating

- Upper-face Glossy

- Strip and Ship

- Zirblast

- Antique Bronze

- Damascus Steel

- Medieval Pewter

- Tumble Polished

Avail our manufacturing services in just 4 simple steps:

-

Register Account

To avail the 3D printing service you must have a customer account registered with us. Create a new customer account here.

-

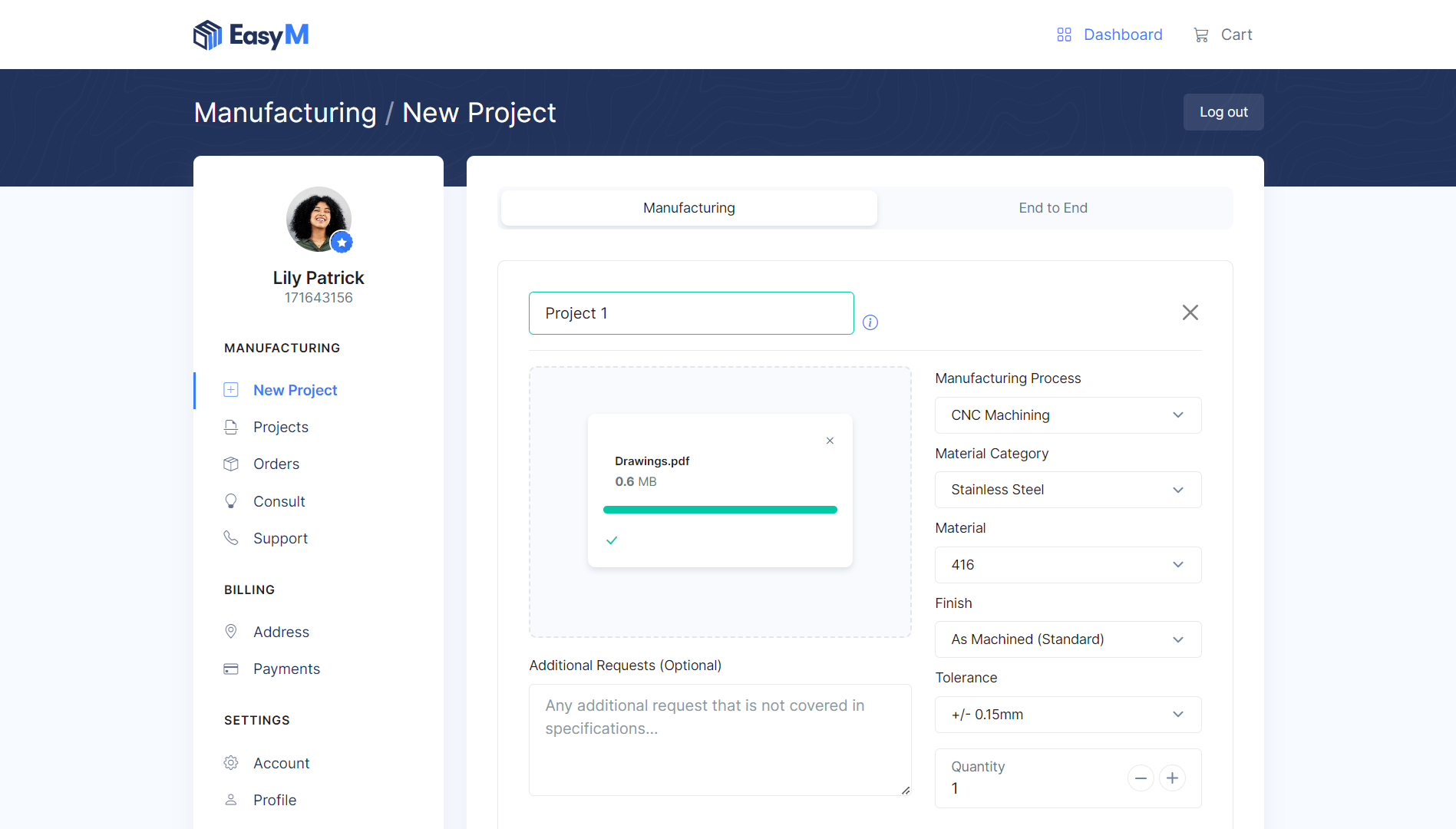

Create Project

Once successfully registered, you will be able to create a new project from your dashboard as shown above.

-

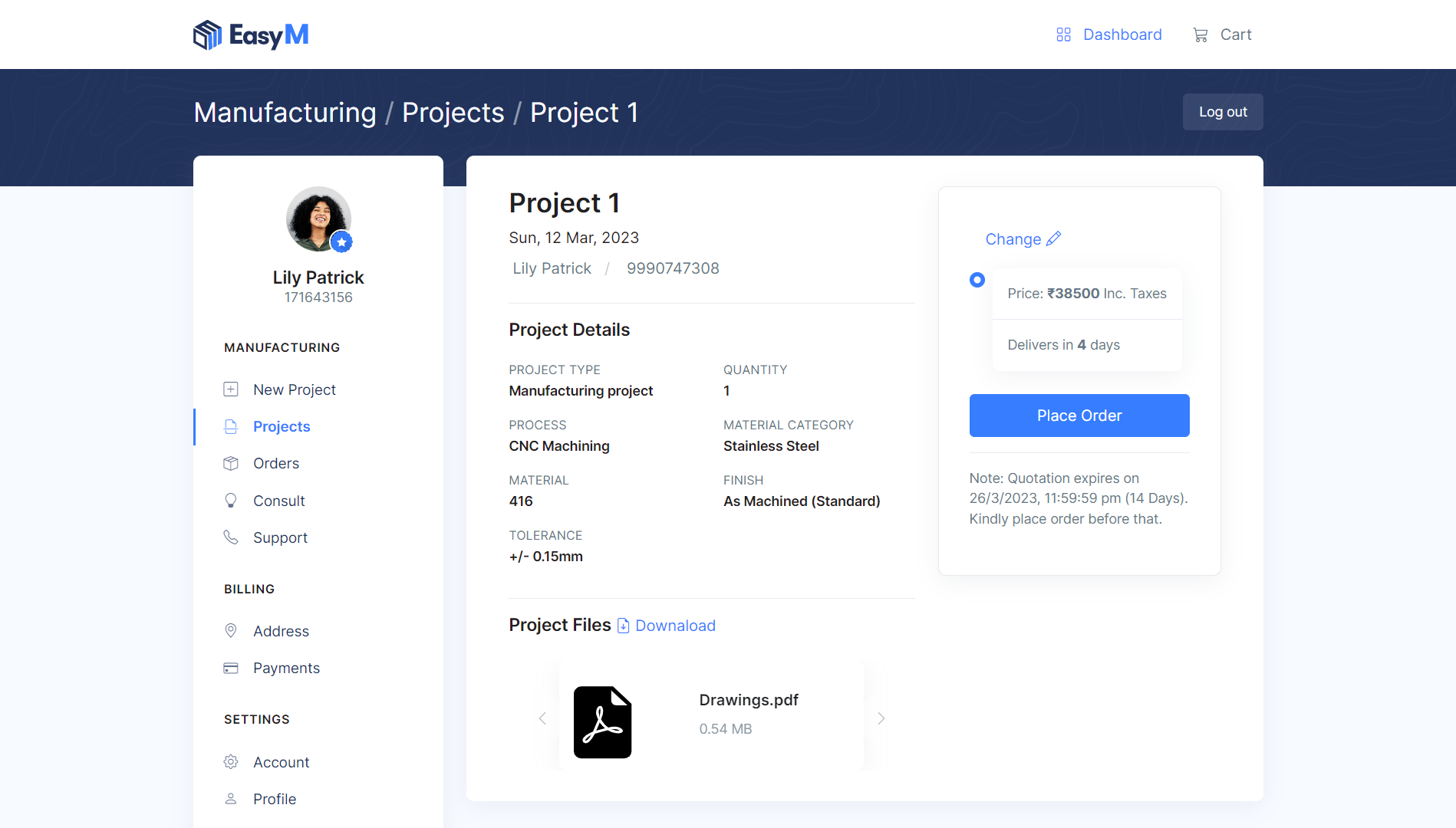

Get Quotation

We will analyse your project and provide you an estimate amount and lead time for completing your project.

-

Place Order

If you are happy with the quotation, click on Place Order as shown above and you will be prompted to the checkout page. Upon successful placement of order, we will immediately start work on your project.

Since each project has custom properties (Part Design, manufacturing process, metarial, finishing and tolerance), it is NOT possible for us to provide pricing details upfront. We evaluate price on case by case basis against each project.