Produce sheet metal parts at your online factory

Have access to unlimited production capacity right from your laptop

Schedule A Call Get QuoteAbout Sheet Metal Fabrication

Advantages

- Cost-effective: Sheet metal is one of the most cost-effective materials available for fabrication. It is also widely available, making it an affordable option for large-scale projects.

- Durability: Sheet metal is highly durable, resistant to wear and tear, and can withstand extreme temperatures, making it an excellent choice for long-term use.

- Versatility: Sheet metal can be formed into a wide range of shapes and sizes, making it ideal for various applications, from architectural components to automotive parts.

- Speed: Sheet metal fabrication can be completed quickly, allowing for rapid prototyping and production.

- Strength: Sheet metal has high strength-to-weight ratio, making it suitable for load-bearing applications.

Disadvantages

- Limited thickness: Sheet metal fabrication has thickness limitations, which may not be suitable for certain applications that require thicker materials.

- Complexity: Complex shapes and designs can be challenging to create using sheet metal fabrication techniques.

- Surface finish: Sheet metal may require additional surface treatments to achieve a desired finish, adding to the cost and time of fabrication.

- Equipment limitations: Sheet metal fabrication requires specialized equipment that may not be available in-house, resulting in higher costs if outsourcing is required.

Applications

- Aerospace: Sheet metal fabrication is used in the production of components for aircraft, such as wings, fuselage, and engine parts.

- Automotive: Sheet metal fabrication is used to manufacture components for vehicles, such as body panels, frames, and chassis.

- Electronics: Sheet metal fabrication is used to create enclosures, brackets, and other components for electronic devices.

- Agriculture: Sheet metal fabrication is used to manufacture components for agricultural equipment, such as tractors, tillers, and plows.

- Military and defense: Sheet metal fabrication is used to manufacture components and equipment for the military and defense industry, such as armored vehicles, missile launchers, and weapon systems.

Why Choose EasyM's Sheet Metal Fabrication Service?

The painful days of searching for right manufacturers, waiting for quotations and parts production are over. EasyM has brought Sheet Metal Fabrication online! We maintain our own Sheet Metal Fabrication facility and a large network of certified manufacturing partners so that we always have someone to work on your orders.

Hate waiting for quotations? We employ dedicated engineers to provide you with an estimate project cost so that you save valuable time. And it does not stop there, our engineers will provide feedback for your designs to make them suitable for manufacturing and reduces cost.

Have a large order with less lead time? No problem. We can parallely process your order at multiple facilities so that you receive your parts on time.

Did not find right materials and finishing? Try us. We offer a wide range of metals and a combination of finishing processes suitable with each material. But wait there is more, if you are unsure about your specifications our engineers will help you select right specifications for your specific use case.

Our Sheet Metal Fabrication portfolio

Steet & Tube Cutting

CNC Bending

Welding & Assembly

FAQs

- Steel

- Stainless Steel

- Aluminium

- Copper

- Bronze

Although the type of finishing process depends on the exact material, here is a combined list of finishing processes that are available:

- Bead Blast

- Anodizing

- Chromate Conversion

- Black Oxide

- Media Tumbled

- Powder Coating

- Hard Chrome Plating

- Electropolishing

- Heat Treatment

- Passivation

- Nickel Plating

- Wet Painting

- Tin Plating

- Vapor Polishing

- Gold Plating

- Silver Plating

- Zinc Plating

- Copper Plating

- Zinc Phosphate Coating

- Cadmium Plating

- Scratch Resistant Coating

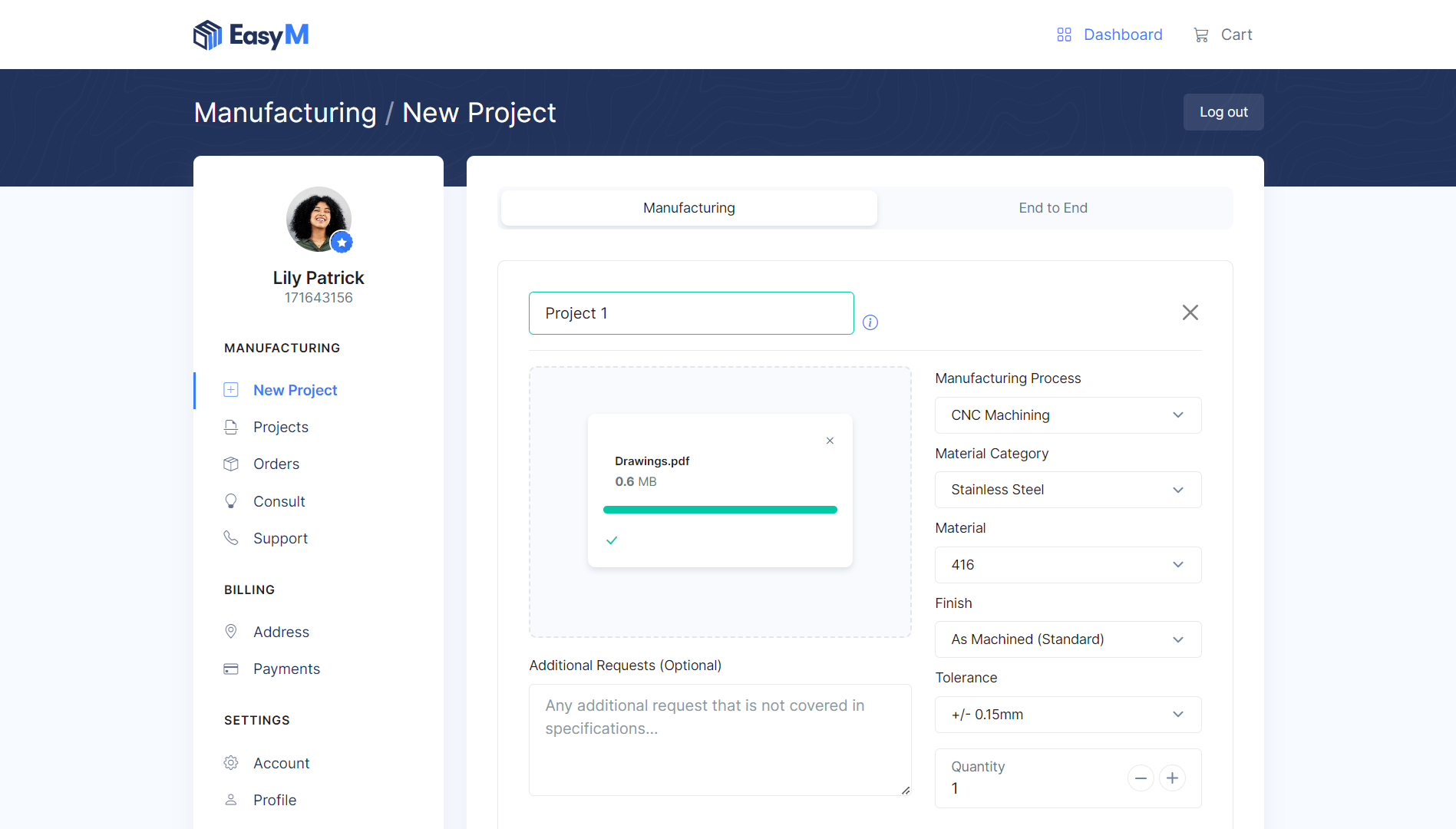

Avail our manufacturing services in just 4 simple steps:

-

Register Account

To avail the sheet metal fabrication service you must have a customer account registered with us. Create a new customer account here.

-

Create Project

Once successfully registered, you will be able to create a new project from your dashboard as shown above.

-

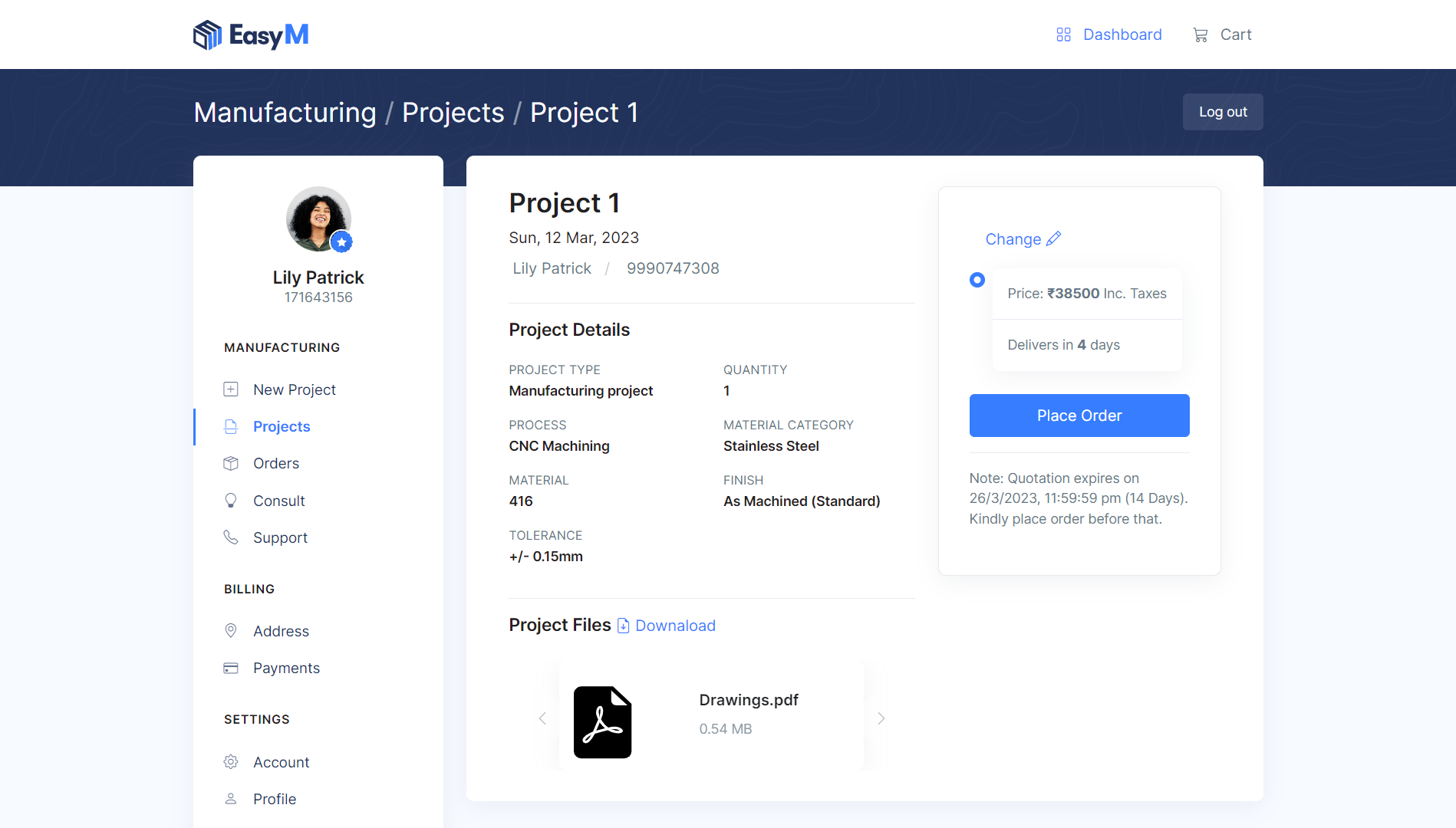

Get Quotation

We will analyse your project and provide you an estimate amount and lead time for completing your project.

-

Place Order

If you are happy with the quotation, click on Place Order as shown above and you will be prompted to the checkout page. Upon successful placement of order, we will immediately start work on your project.

Since each project has custom properties (Part Design, manufacturing process, metarial, finishing and tolerance), it is NOT possible for us to provide pricing details upfront. We evaluate price on case by case basis against each project.