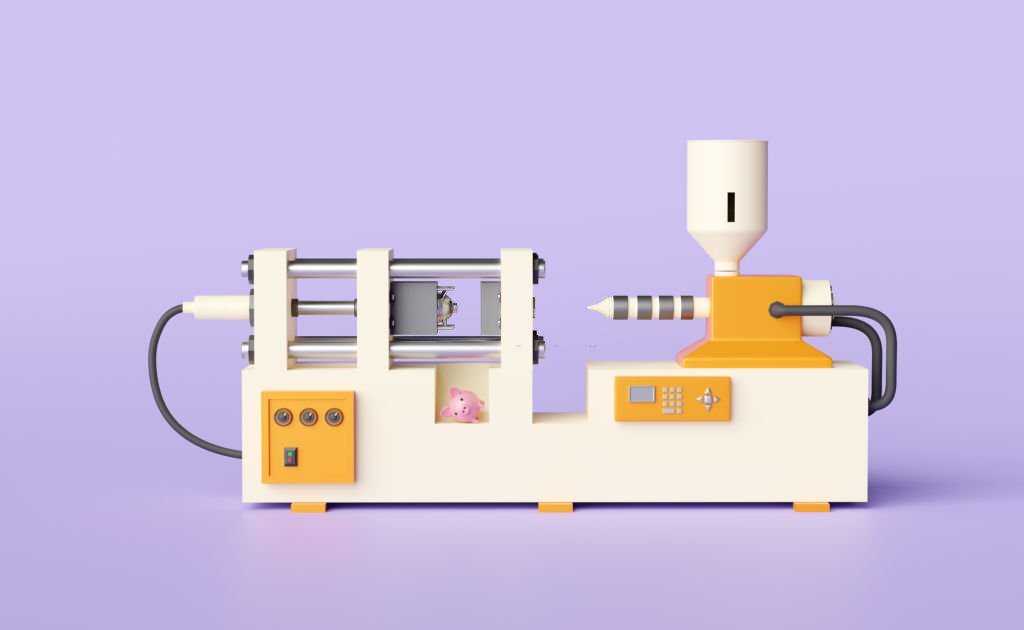

Produce high volume complex parts with our injection molding service

Best suited for high volume production runs

Schedule A Call Get QuoteAbout Injection Molding

Advantages

- High production efficiency: Injection molding is a highly automated process that can produce large quantities of identical parts quickly and consistently.

- Wide range of materials: Injection molding can be used with a variety of materials, including thermoplastics, thermosets, and elastomers.

- High accuracy and complexity: Injection molding can produce parts with high accuracy and complex shapes, including intricate geometries and thin walls.

- Low labor costs: Once the tooling is set up, injection molding requires minimal labor to operate, resulting in lower labor costs per part.

- Reduced waste: Injection molding generates less waste compared to other manufacturing methods, as scrap material can be reground and reused.

Disadvantages

- High tooling costs: Injection molding requires expensive tooling to be created, which can be cost-prohibitive for small production runs.

- Long lead times: It can take several weeks or even months to design and build injection molding tooling, resulting in longer lead times for production.

- Limited flexibility: Once the tooling is created, it is difficult and expensive to make changes to the design or material being used.

- Part size limitations: Injection molding is typically used for small to medium-sized parts, and larger parts may require a different manufacturing process.

- Environmental impact: The injection molding process can generate plastic waste, which can have negative environmental consequences

Applications

- Automotive: Injection molding is used to produce a wide variety of automotive parts, such as dashboard panels, door handles, and ventilation ducts.

- Consumer goods: Injection molding is used to produce a wide variety of consumer goods, such as toys, kitchen utensils, and electronic enclosures.

- Medical equipment: Injection molding is used to produce a wide variety of medical equipment and devices, such as syringes, IV components, and surgical instruments.

- Packaging: Injection molding is used to produce a wide variety of packaging materials, such as plastic bottles, caps, and closures.

- Aerospace: Injection molding is used to produce a variety of aerospace components, such as interior and exterior panels, brackets, and electrical connectors.

Why Choose EasyM's Injection Molding Service?

The painful days of searching for right manufacturers, waiting for quotations and parts production are over. EasyM has brought injection molding online! We maintain our own injection molding facility and a large network of certified manufacturing partners so that we always have someone to work on your orders.

Hate waiting for quotations? We employ dedicated engineers to provide you with an estimate project cost so that you save valuable time. And it does not stop there, our engineers will provide feedback for your designs to make them suitable for manufacturing and reduces cost.

Have a large order with less lead time? No problem. We can parallely process your order at multiple facilities so that you receive your parts on time.

Did not find right materials and finishing? Try us. We offer a wide range of metals and a combination of finishing processes suitable with each material. But wait there is more, if you are unsure about your specifications our engineers will help you select right specifications for your specific use case.

FAQs

- Rigid Plastics

- Elastomers/Rubber

- Stainless Steel

- Low-Alloy Steel

- Tool Steel

- Soft Magnetic Steel

- Tungstun Heavy Alloy

- WC-Co Cemented Carbide

- SPI A-1

- SPI A-2

- SPI A-3

- SPI B-1

- SPI B-2

- SPI B-3

- SPI C-1

- SPI C-2

- SPI C-3

- SPI D-1

- SPI D-2

- SPI D-3

- MT-11010

- MT-11020

- MT-11030

- VDI 12

- VDI 15

- VDI 18

- VDI 21

- VDI 24

- VDI 27

- VDI 30

- VDI 33

- VDI 36

- VDI 39

- VDI 42

- VDI 45

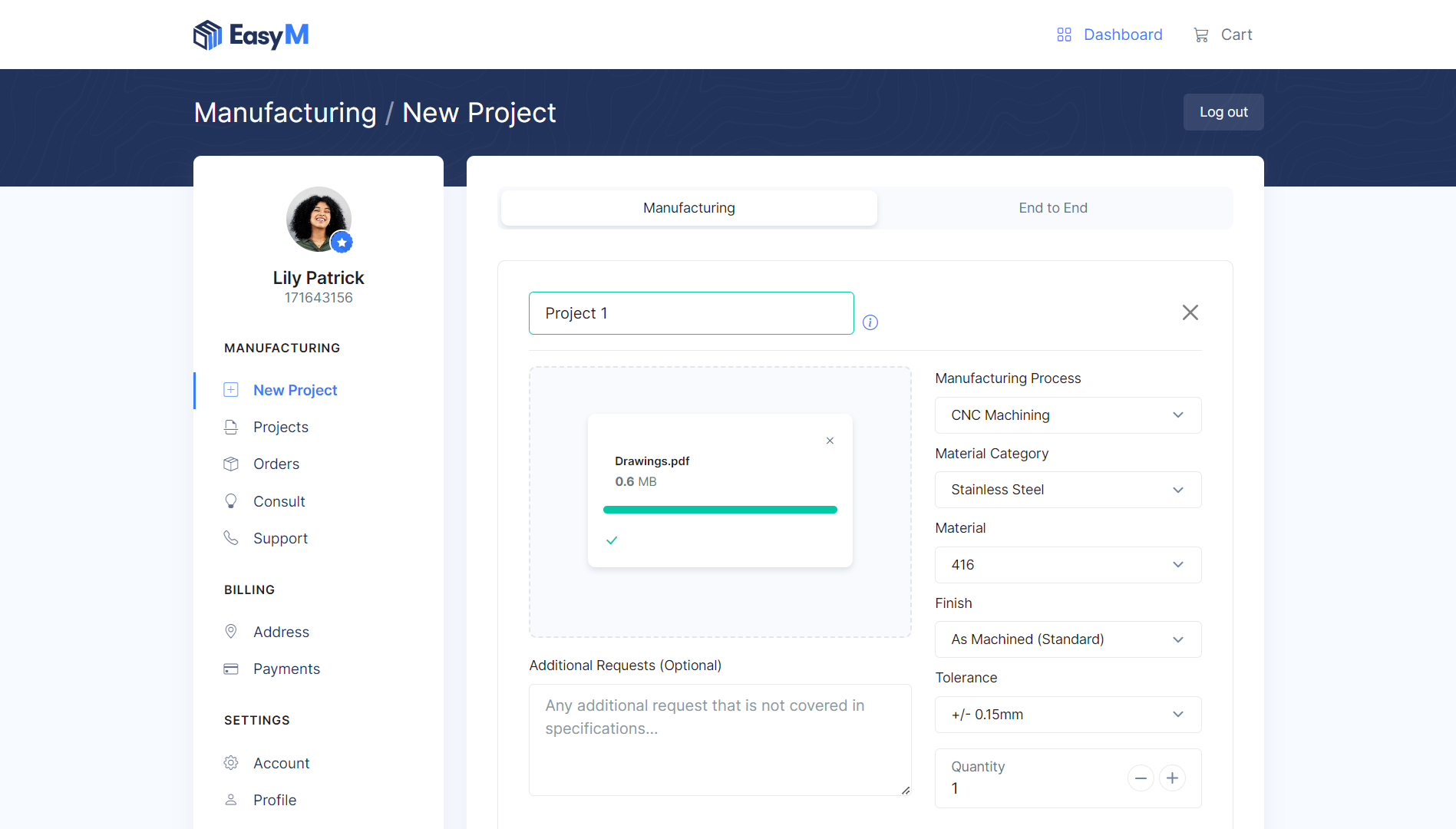

Avail our manufacturing services in just 4 simple steps:

-

Register Account

To avail the injection molding service you must have a customer account registered with us. Create a new customer account here.

-

Create Project

Once successfully registered, you will be able to create a new project from your dashboard as shown above.

-

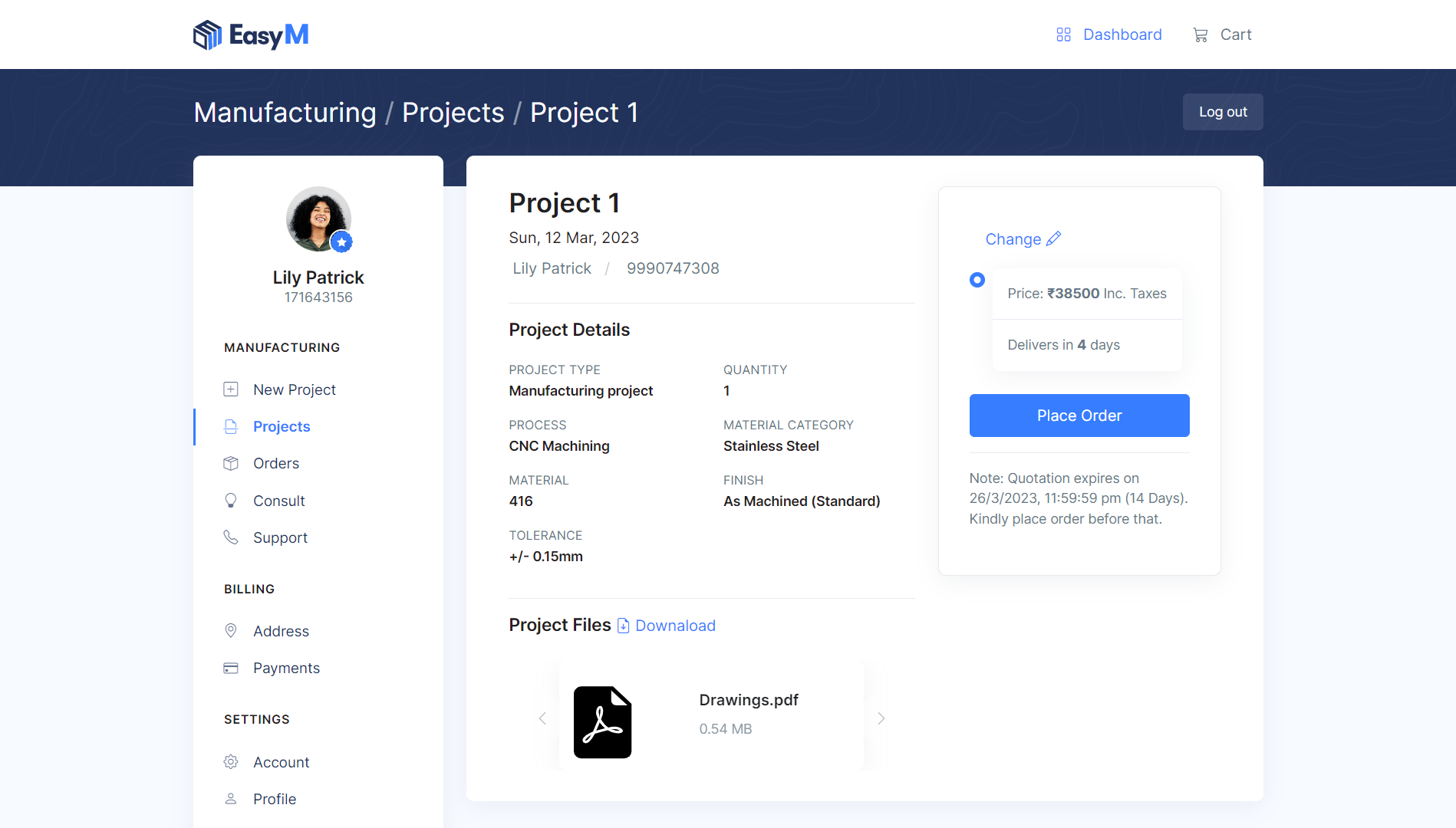

Get Quotation

We will analyse your project and provide you an estimate amount and lead time for completing your project.

-

Place Order

If you are happy with the quotation, click on Place Order as shown above and you will be prompted to the checkout page. Upon successful placement of order, we will immediately start work on your project.

Since each project has custom properties (Part Design, manufacturing process, metarial, finishing and tolerance), it is NOT possible for us to provide pricing details upfront. We evaluate price on case by case basis against each project.