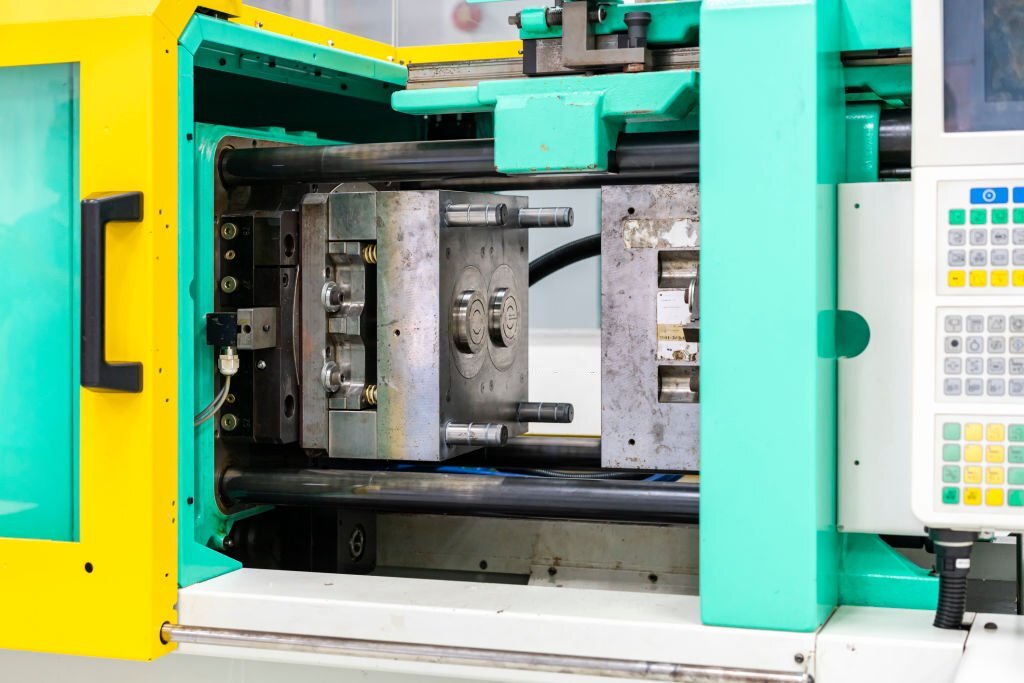

Produce high volume complex parts with our die casting service

Best suited for high volume production runs

Schedule A Call Get QuoteAbout Die Casting

Advantages

- High production rate: Die casting is a high-speed process that can produce a large number of parts in a short time.

- Dimensional accuracy and consistency: Die casting produces parts with high dimensional accuracy and consistency, resulting in parts that fit together precisely.

- Excellent surface finish: Die casting produces parts with a smooth surface finish, requiring little or no additional finishing.

- Good strength: Die-cast parts are strong and can withstand high loads and stresses.

- Variety of materials: Die casting can be used with a wide range of metals and alloys, including aluminum, zinc, magnesium, and copper.

Disadvantages

- High cost: Die casting requires expensive equipment and tooling, making it more expensive than other casting processes.

- Limited part size: The size of die-cast parts is limited by the size of the die casting machine, making it unsuitable for larger parts.

- Limited design flexibility: Die casting requires specific design considerations, such as uniform wall thickness, to ensure successful casting.

- Porosity: Die-cast parts can sometimes have porosity or air pockets due to the injection of molten metal into the die.

- Environmental concerns: Die casting produces waste material and uses large amounts of energy, raising environmental concerns.

Applications

- Aerospace: CNC machines are widely used in aerospace industry for manufacturing complex and precision parts for aircrafts, satellites and spacecrafts.

- Automotive: CNC machining is extensively used in the automotive industry for manufacturing engine components, transmission parts, chassis components, and other automotive parts.

- Medical: CNC machines are used in the medical industry for manufacturing surgical instruments, implants, prosthetics, and other medical devices.

- Electronics: CNC machines are used in the electronics industry for manufacturing parts for computers, smartphones, and other electronic devices.

- Defense: CNC machining is used in the defense industry for manufacturing parts for military equipment such as tanks, aircrafts, and weapons.

Why Choose EasyM's Die Casting Service?

The painful days of searching for right manufacturers, waiting for quotations and parts production are over. EasyM has brought die casting online! We maintain our own die casting facility and a large network of certified manufacturing partners so that we always have someone to work on your orders.

Hate waiting for quotations? We employ dedicated engineers to provide you with an estimate project cost so that you save valuable time. And it does not stop there, our engineers will provide feedback for your designs to make them suitable for manufacturing and reduces cost.

Have a large order with less lead time? No problem. We can parallely process your order at multiple facilities so that you receive your parts on time.

Did not find right materials and finishing? Try us. We offer a wide range of metals and a combination of finishing processes suitable with each material. But wait there is more, if you are unsure about your specifications our engineers will help you select right specifications for your specific use case.

FAQs

- Aluminium

- Zinc

Although the type of finishing process depends on the exact material, here is a combined list of finishing processes that are available:

- Bead Blast

- Anodizing

- Chromate Conversion

- Black Oxide

- Media Tumbled

- Powder Coating

- Hard Chrome Plating

- Electropolishing

- Heat Treatment

- Passivation

- Nickel Plating

- Wet Painting

- Tin Plating

- Gold Plating

- Silver Plating

- Zinc Plating

- Copper Plating

- Zinc Phosphate Coating

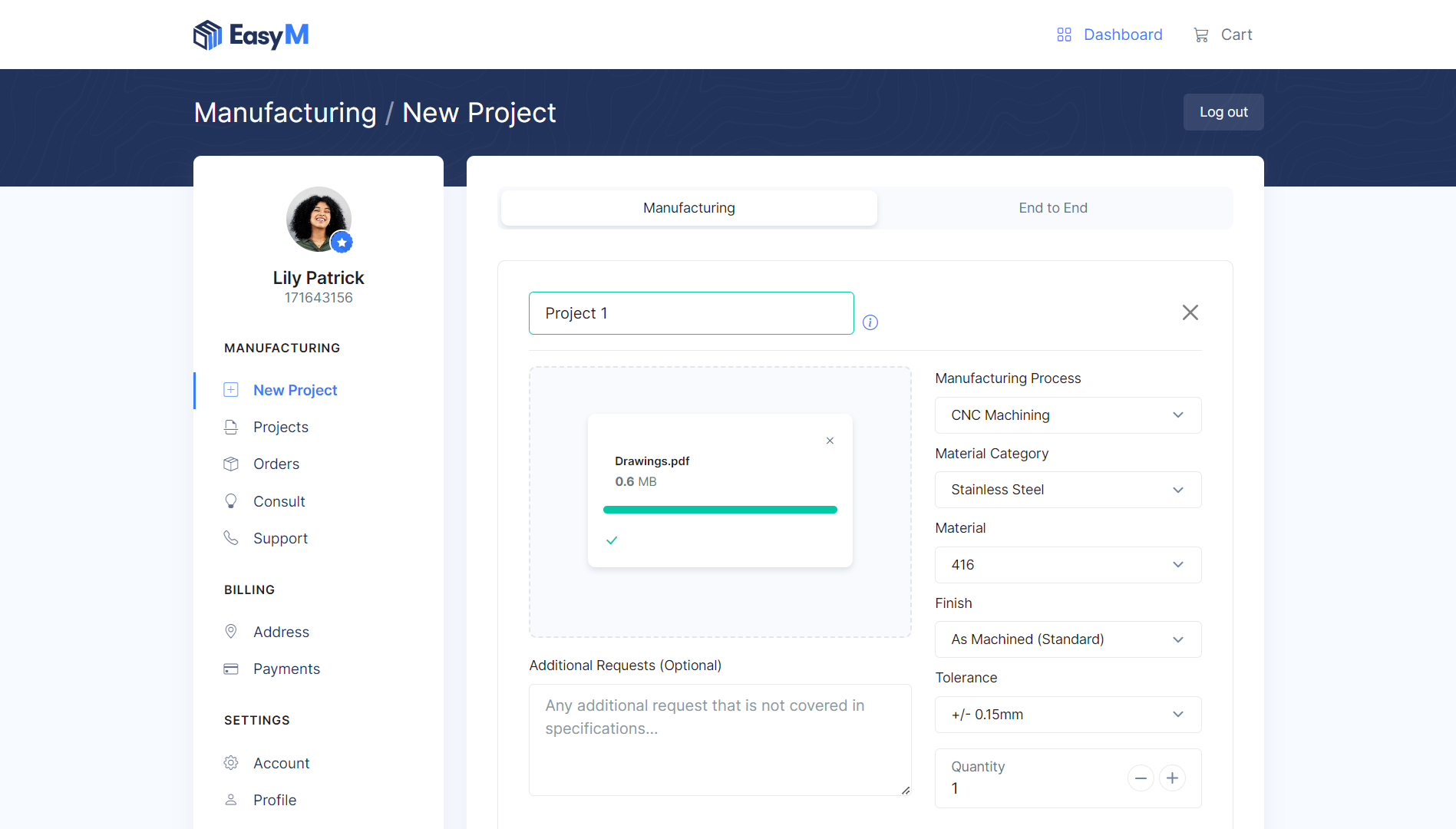

Avail our manufacturing services in just 4 simple steps:

-

Register Account

To avail the die casting service you must have a customer account registered with us. Create a new customer account here.

-

Create Project

Once successfully registered, you will be able to create a new project from your dashboard as shown above.

-

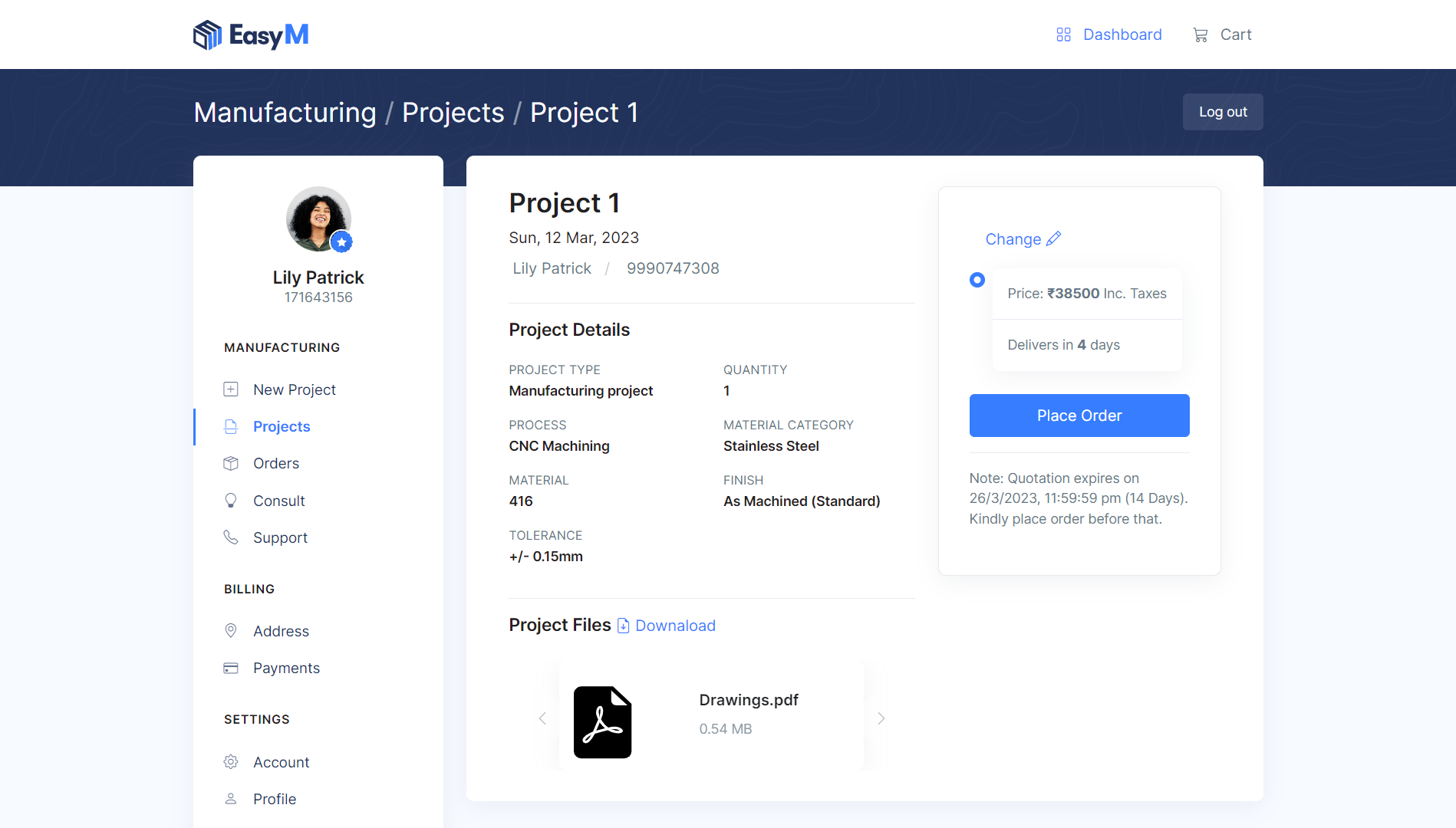

Get Quotation

We will analyse your project and provide you an estimate amount and lead time for completing your project.

-

Place Order

If you are happy with the quotation, click on Place Order as shown above and you will be prompted to the checkout page. Upon successful placement of order, we will immediately start work on your project.

Since each project has custom properties (Part Design, manufacturing process, metarial, finishing and tolerance), it is NOT possible for us to provide pricing details upfront. We evaluate price on case by case basis against each project.